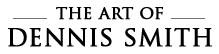

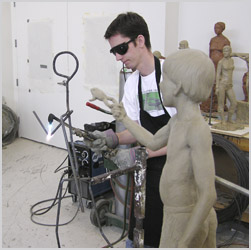

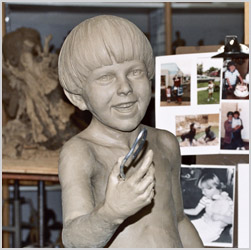

Bronze Process

Bronze casting dates back to the ancient Chinese and the process has largely remained unchanged for thousands of years. The sculptures are cast using the traditional lost-wax method. Today the process is improved by mechanized tools but the process remains the same.